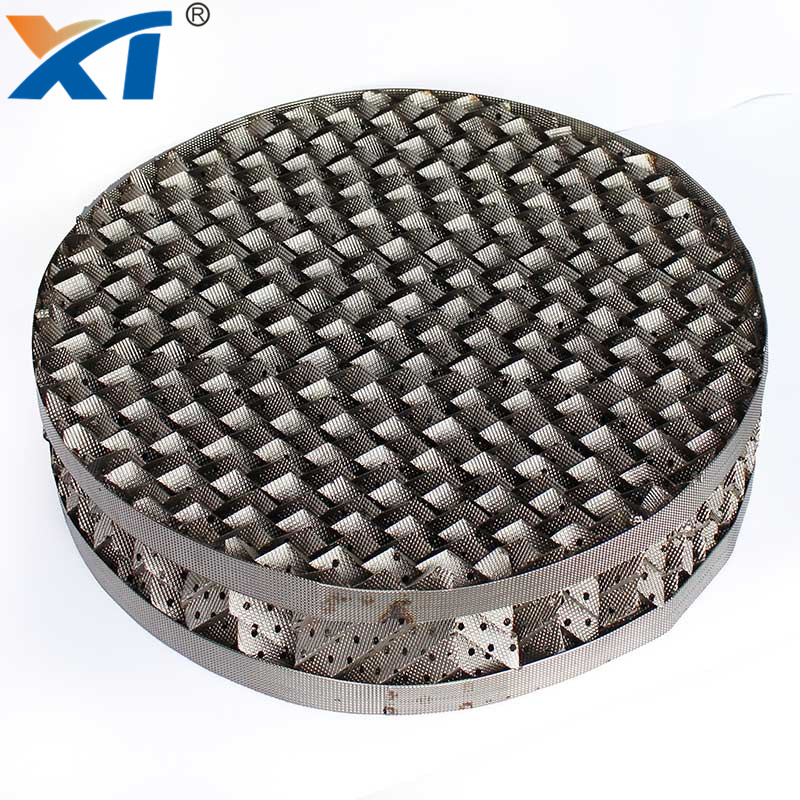

XINTAO Metal Perforated Corrugated Packing is a structured packing formed by punching holes on the surface of metal sheets, rolling small lines, and then assembling large corrugations. Compared with other structured packings, it has good anti-blocking performance.

The main material of Metal Perforated Corrugated Packing is stainless steel 304, 316, 316L and carbon steel. It is especially suitable for large-diameter towers and occasions with large gas-liquid load. The effect of transforming the plate tower with Metal Perforated Corrugated Packing is particularly obvious.

The main feature of Metal Perforated Corrugated Packing is that the stainless steel metal belt is directly embossed, and then punched into corrugated sheets, which are then assembled into packing discs. The height of each disc unit is 50-200mm, the diameter is more than 1.5m, and the packing is made into blocks. Metal Perforated Corrugated Packing is a kind of packing that is arranged in a uniform geometric figure and neatly stacked in the tower. It specifies the gas-liquid flow path, the pressure drop can be small, but it provides more specific surface area, and can achieve higher mass transfer and heat transfer effects in the same volume. Due to the uniformity, regularity and symmetry of the structure, When it has the same specific surface area as the bulk packing, the porosity of the stainless steel orifice corrugated packing is larger, has a larger flux, and the comprehensive processing capacity is much larger than that of the plate tower and the bulk packing tower. Various general-purpose structured packings represented are used in industry. Through careful design, manufacture, installation and careful operation, etc., it can be achieved that the industrial amplification effect is not obvious. The implementation standard of Metal Perforated Corrugated Packing refers to the standard number HG/T 21559.2-2005 chemical industry standard.

What are the applications of Metal Perforated Corrugated Packing?

Metal orifice corrugated series packing has a wide range of uses in mass transfer equipment in distillation, rectification, absorption, desorption, extraction, chemical exchange, washing, regeneration, heat transfer, stripping, flash evaporation, foam trapping and other occasions. It has larger flux and higher separation efficiency. It can also be used in three-phase separators or two-phase separators in crude oil and natural gas processing as oil-water separator packing, coalescing plate packing, and vapor-liquid separation packing. Metal Perforated Corrugated Packing is used in the following categories:

Metal Perforated Corrugated Packing is used in petrochemical industry: ethylene/styrene separation, high-purity oxygen preparation, superimposed oil separation, propylene oxide separation, butanizer, cyclohexane recovery, gasoline fractionation, atmospheric and vacuum oil refining, gasoline Demercaptan, formaldehyde absorption tower, ring recovery tower, gasoline fractionation tower, catalytic reforming pre-fractionation tower, oil refinery lubricating oil type vacuum tower, refinery catalytic cracking unit stabilization tower, aromatics separation and solvent oil separation tower, depropane tower, pressurized distillation tower.

Metal Perforated Corrugated Packing is applied to the fertilizer industry: comprehensive scrubbing tower for gas production, saturated hot water tower, ammonia recovery tower, desorption tower, replacement of saturated hot water tower, decarbonization tower, methanol rectification tower, nitro compound fertilizer project Ammonia recovery tower, washing tower, ammonia-air mixer in the middle;

Metal Perforated Corrugated Packing is applied to the environmental protection industry: recovery of nitrogen-containing ammonia, recovery of waste acetone, recovery of high-purity dimethylformamide, acid sewage stripper and other devices;

Metal Perforated Corrugated Packing is applied to coal chemical industry: benzene washing tower, desulfurization tower, benzene removal tower, replacement degreaser, high pressure ammonia washing tower, water washing tower, deoiling tank, methanol absorption tower for recovering crude benzene in coke oven gas in coking plant , water gas desulfurization tower, stripper purification device in coal-to-urea project;

Oil and gas treatment: used as oil-water separator packing, coalescing plate packing, vapor-liquid separation packing in three-phase separator or two-phase separator in crude oil and natural gas processing.

More details, please contact us:

E:info@xintaokeji.com

https://www.xintaokeji.com/