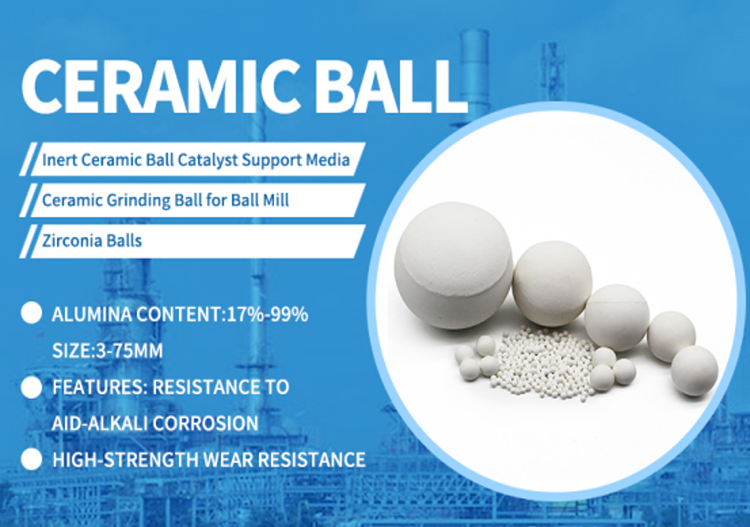

Alumina ceramic balls are a high-temperature material with excellent properties such as acid resistance, alkali resistance, high temperature resistance, and high hardness. They are widely used in chemical industry, petroleum, electric power, metallurgy and other fields. The following is the production process of alumina ceramic balls.

1. Raw material preparation:

The main raw material of alumina ceramic balls is high-purity alumina powder. During the production process, certain additives and binders need to be added. Raw materials should undergo pre-treatment such as screening and drying to ensure uniform particle size and appropriate moisture content.

2. Mixing and Granulating

After the pretreated raw materials are mixed evenly, a granulator is used to press them into uniform spherical particles. The pressure and speed need to be controlled during granulation to ensure the density and shape of the granules.

3. Drying

The granulated alumina ceramic balls need to be dried to remove residual moisture and additives. Drying temperature and time need to be controlled according to specific conditions, generally at a temperature of 100-150°C for several hours.

4. Sintering

The dried alumina ceramic balls need to be sintered. The sintering temperature is generally between 1500-1700°C, requiring long-term high-temperature treatment. During the sintering process, the binder is burned away and the additives make the alumina particles denser and stronger.

5. Quality inspection and packaging

After sintering is completed, the alumina ceramic balls need to be inspected to see if their appearance and physical properties meet the requirements. Qualified products will be packaged and sealed for storage and transportation.

In short, the production process of alumina ceramic balls requires multiple steps, including raw material preparation, mixing and granulation, drying, sintering and quality inspection. In each step, parameters such as temperature, pressure, speed, etc. need to be controlled to ensure the quality and performance of the final product.

If you are interested in this item, please do not hesitate to send your specific inquiry to info@xintaokeji.com