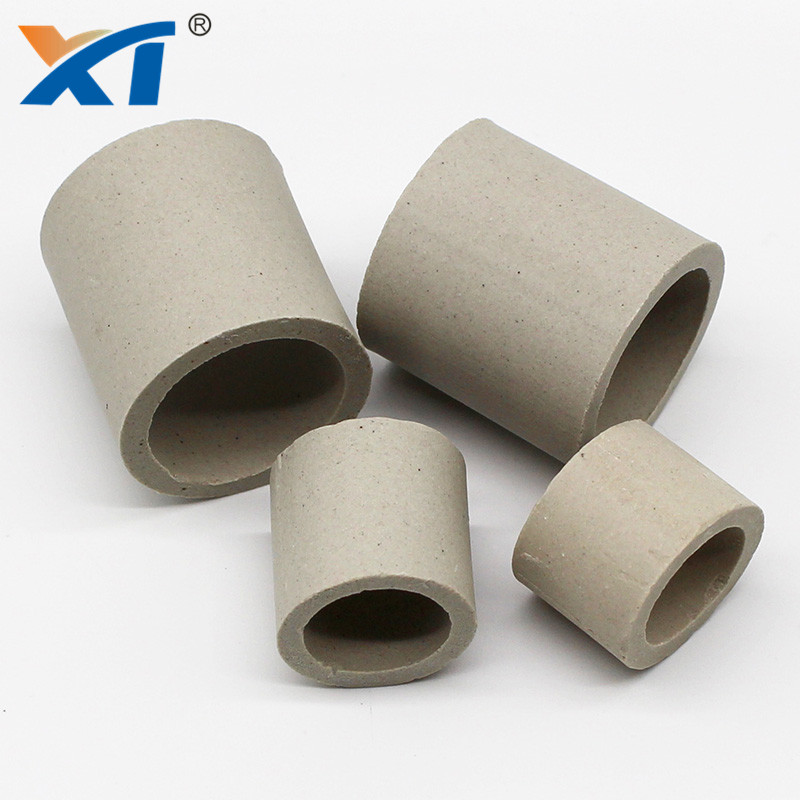

Ceramic Rasching Ring is the first development of random industrial pac-king.It is designed for mass transfer, heat transfer, as well

as modern distillation and separation industrial equipment.

It has excellent acid resistance and heat resistance performance.

It can resist to corrosion of various inorganic acids, organic acids and organic solvents except hydrofluoric acid, and can be used in high or low temperature conditions.

Raschig Rings are available to the order of sizes: 15 mm,16mm,25 mm,40mm,50 mm,80 mm,100 mm,150mm. The height and diameter of ceramic rasching ring are the same.

The purpose of using Ceramic Raschig Ring – is mixing, redistributing the active mass, increasing contact between the surfaces of the liquid and gas phases, and improving heat transfer processes in equipment.

The wall thickness of ceramic rasching ring should be thinner under acceptable strength. Though the mass transfer of ceramic rasching ring is low, but it is much cheaper than other random packing, so it is still widely accepted in some industries.

Application:

It can be used in the drying columns, absorbing columns, cooling

towers, scrubbing towers and actifier columns in chemical industry, metallurgy industry, coal gas industry, oxygen producing industry, etc.

Features & Benefits

Economical and low price.

Simple structure.

Acid and alkali resistance.

High or low temperature resistance.

More details, welcome to contact us:

E: info@xintaokeji.com