1.Why choose 3A molecular sieve for ethanol drying?

----The diameter of water molecule is 2.6angstroms(2.6A),which is a high polar molecule,easily adsorbed by molecular sieve.Once the water molecule is been adsorbed,it will fixed on the crystalloid.

The diameter of ethanol molecule is 3.7angstroms(3.7A).According the diameter difference between water molecule and ethanol molecule,we choose 3A as a absorbent for ethanol drying.

2.The principle of vapor phase dehydration of alcohol

Molecular sieve has strong adsorption capacity for vapor phase water molecule under high temperature. Heating the alcohol vapor which is with 95% alcohol content to a certain temperature,then put into the molecular sieve adsorption tower.In the process when the water molecule in the alcohol vapor pass through the molecular sieves,the water molecule is adsorbed by the molecular sieves porous,now we have done with the ethanol dehydration.After condense and form the ethanol vapor,we can have 99.5%~99.9%(V/V) waterfree ethanol.

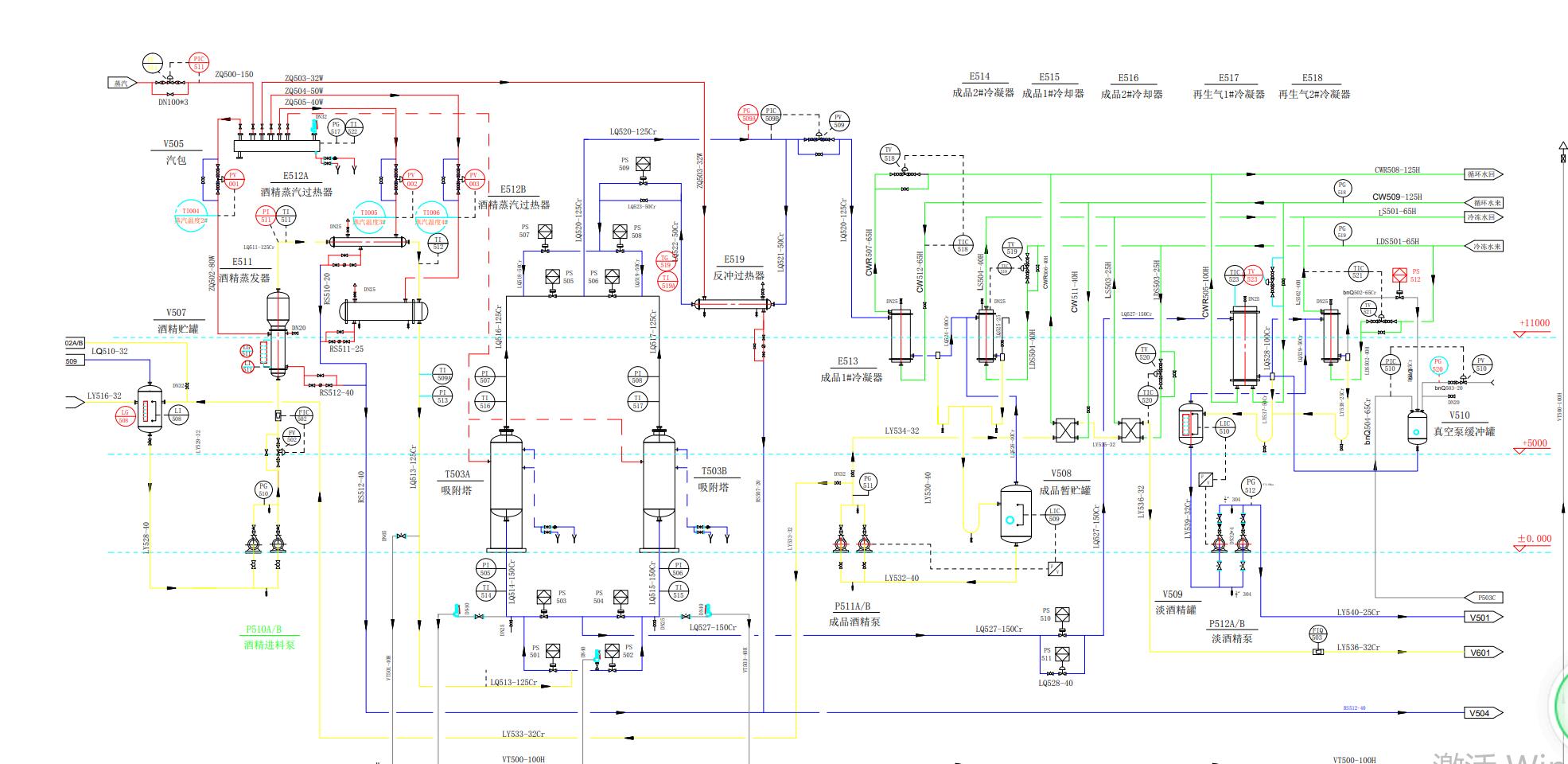

3.Production Process

a. Tower A: Adsorption System

Put the 95% alcohol into the preheater→use boiler steam and heat to 100-120℃→enter the evaporator to steam it to 105-125℃→enter the superheater,use high pressure steam heat it to 130℃-145℃ overheated state→enter molecular sieve adsorption tower A→molecular sieve absorb the gaseous water molecules in the alcohol vapor→condense and cool the vapor(use condensator)→9935-99.9% waterfree ethanol.

Remark:*the heat source of the evaporator is the boiler steam

*the condensing system use circulating water for cooling

b. Tower B: Dehydration and Regeneration System

Absolute alcohol (waterfree ethanol)→use high pressure steam as hear source heating in the superheater to 180℃~230℃, as a molecular sieve regeneration carrier.→enter molecular sieves tower B→under high temperature and low pressure,the H2O in the molecular sieve is removed.

Tower A and Tower B alternately process the adsorption and regeneration.

4.Operation Precautions

a. Molecular sieve replacement regeneration procedure must be taken before go into operation.

b. Temperature of the alcohol steam which enter the molecular sieve tower must be controlled strictly to avoid the form of liquid phase alcohol.

c. The molecular sieve as desiccant cannot be exposed in the open air and should be stored in dry condition with air-proof package while the machine is out of running.

5.The application of our molecular sieve to get waterfree ethanol

To create a highly-refined ethanol product, the Pressure Swing Adsorption (PSA) method is combined to the standard multi-pressure distillation process, which includes our 3A Molecular Sieves as adsorbents. In this process, water molecular sieves are drawn out and adsorbed by the pores of the molecular sieves, allowing only the ethanol to pass through. The process results in a final ethanol product that has a purification of 99.8%.