The molecular sieve adsorption for ethanol dehydration is developed in the past 20 years, and it has been applied on a large scale in industry.

Compared with other methods, the method has the following characteristics: (1) Lower energy consumption. (2) Easy to operate. (3) It can be collected in the whole process with automatic control. (4) No toxic chemicals were used in the whole process.

Why it is 3A molecular sieve

The diameter of the water molecule is 2.6A, it’s highly polar molecules. The molecular sieve has a strong adsorption capacity for polar molecules.

The diameter of the alcohol molecule is 4.7A.

3A molecular sieve is a kind of alkali metal Aluminosilicate. It’s Synthetic zeolite. The pore size of the molecular sieve is 3A.It will not adsorb any molecules larger than 3A in diameter. So it just adsorb water molecule instead of alcohol molecule.

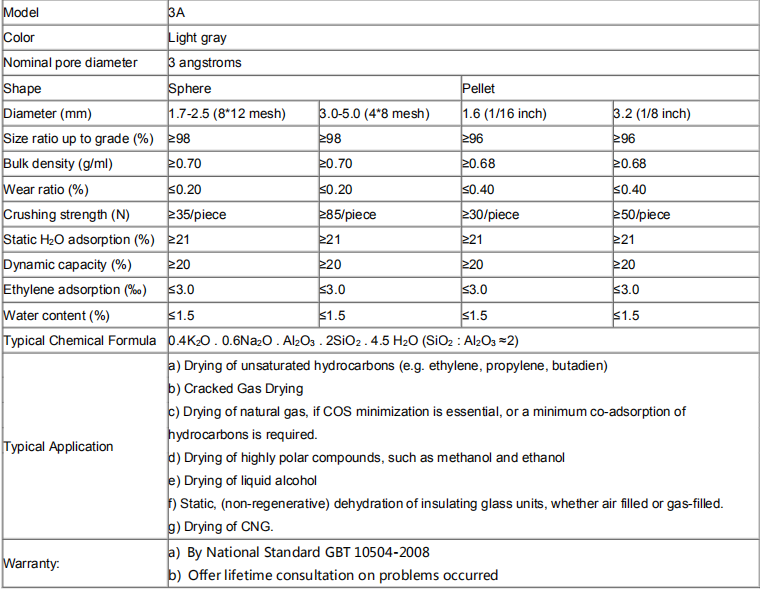

Our 3A molecular sieve technical indicators

The Principle of Vapor Phase Ethanol Dehydration

Molecular sieve has a strong adsorption capacity for water molecules when it’s in vapour phases at high temperature. So when a concentration of 95% alcohol vapour is superheated to certain temperature, it will pass molecular sieve bed. The water molecules in alcohol vapour will be adsorbed by 3A molecular sieve. Then the water molecules and alcohol will be separated.

Purified alcohol will be through condensation, cool and it comes out alcohol with concentration of 99.5% ~99.9% Vol.

Adsorption system

There will be two towers of molecular sieve bed ǀ and ǁ. When one tower is adsorption and another tower will desorption. Then two towers recycle for adsorption and desorption.

Operation precautions

a. Before the system is on operation, molecular sieve must be regenerated;

b. The recycle time of one adsorption and desorption is adjusted according to the water content of the anhydrous alcohol product;

c. In case of liquid alcohol in molecular sieve bed, the temperature of the alcohol vapor entering into the molecular sieve bed must be strictly controlled to meet the temperature requirement of molecular sieve.

d. Strictly control the exhaust gas temperature of ǁ desorption condenser to prevent the loss of alcohol with non-condensable gas due to excessive temperature;

e. The system cannot be over pressure state.

f. In case of long time shutdown, the molecular sieve bed should be completely isolated to prevent the molecular sieve from adsorbing moisture in the air.