*Product Description:

13X-HP high-efficiency oxygen molecular sieve is a new type of X-type molecular sieve,which is mainly used in pressure swing adsorption oxygen production process.It has a high Nitrogen adsorption capacity and an excellent nitrogen and oxygen separation coefficient.It can significantly increase the economic benefits of oxygen production by lowering operating cost and energy consumption.They are the substitute of 5A (CaA) type molecular sieve.

XINTAO Molecular Sieve 13X-HP model XT-501 is designed for PSA portable medical oxygen concentrator 1-5L/Min.Oxygen purity can up to 93±3%.

XINTAO Molecular Sieve 13X-HP model XT-502 is designed for industrial oxygen plant.Oxygen purity can up to 93±3%.

*Technical Parameter:

Item | Molecular Sieve 13X-HP | |

Color | Light gray | |

Nominal pore diameter | 10 angstroms | |

Shape | Sphere (ball) | |

Model | XT-501 | XT-502 |

Diameter (mm) | 0.4-0.8 | 1.6-2.8 |

Loss on Ignition (wt%.575℃, 1hr) | ≤1.0 | ≤1.0 |

Bulk density (g/ml) | ≥0.62 | ≥0.62 |

Crushing strength (N) | / | 25+-3/piece |

Static H2O capacity (wt% RH60%,25℃) | ≥30 | ≥30 |

Static CO2 capacity(wt% 250mmHg, 25℃) | ≥19.8 | ≥19.8 |

Attrition (wt%) | ≤0.2 | ≤0.2 |

Particle Ration (%) | ≥95 | ≥97 |

N2 capacity(ml/g,) | ≥8 | ≥8 |

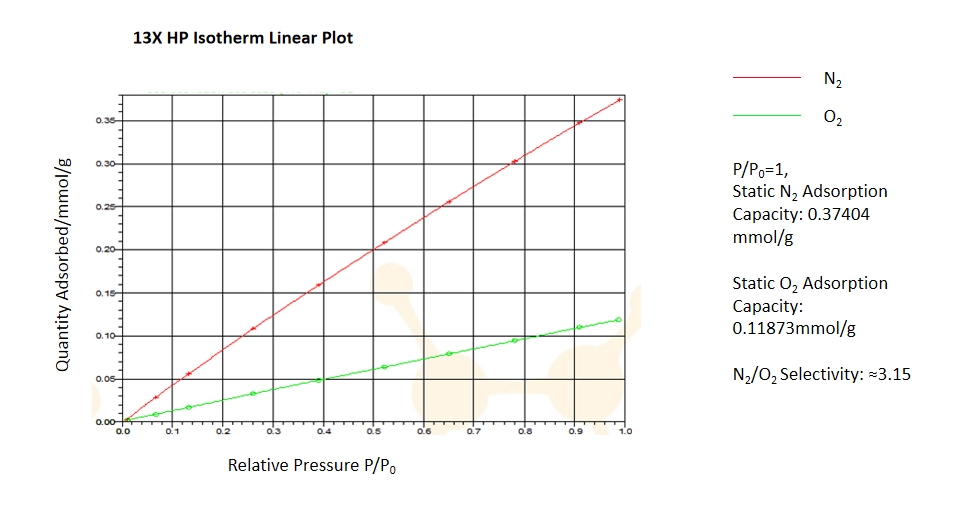

N2/O2 Separation Coefficient(a,) | ≥3.15 | ≥3.15 |

Concentration of O2 | 93%+-3% | 93%+-3% |

*N2 & O2 Separation Coefficient Chart:

*Applications:

XINTAO Molecular Sieve 13X- HP is mainly used in PSA industrial oxygen production and medical center oxygen supply systems.

Such as in hospital oxygen generator,waste water treatment field, aquaculture field for fish farming, ozone production filed as well as used in potable PSA generator for medical oxygen market.

*Hand & Storage Recommendation:

The product as desiccant cannot be exposed in the open air and should be stored in dry condition with air-proof package under the temperature of -10 ~ 45℃ and avoid direct sunlight!

*Regeneration Method:

XINTAO Molecular sieve can be regenerated by either heating in the case of thermal swing process or by lowering the pressure in the case of pressure swing process. Put the molecular sieve in a vacuum muffle furnace for one hour at 550℃.

*Packaging:

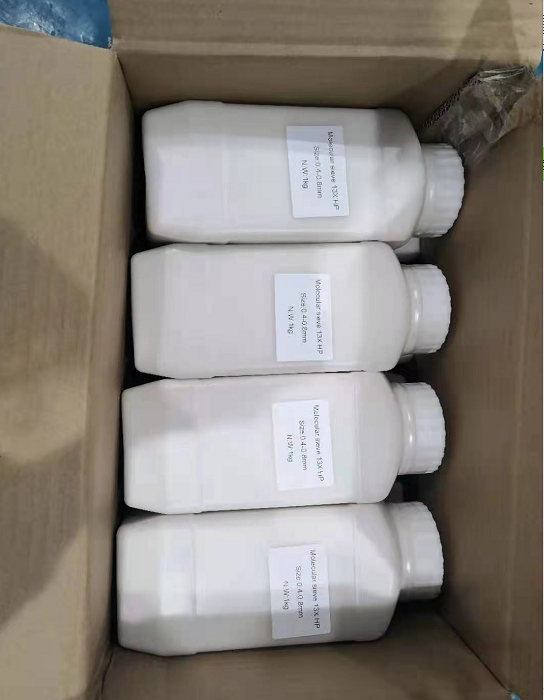

1. Sample packaging:1kg/plastic bottle+carton box. 20kgs per carton box.

2. Bulk order packaging:

①13X-HP bead size 0.4-0.8mm: 25kg/steel drum,wooden palletized with film wrapped. 500kg/600kg per pallet.

②13X-HP bead size 1.6-2.5mm: 125kg/steel drum,4 drums in one wooden pallet.500kg per pallet.

*FQA

1. How many kilograms of zeolites to install in a 3L oxygen concentrator?

----Size of the sieve tank is 5.2cm*19cm,need 0.5kg zeolites.

2. How many kilograms of zeolites to install in a 5L oxygen concentrator?

----Size of the sieve tank is 7.8X42cm,need 2.5kg zeolites.

3. How long is the shelf-life of molecular sieve?

----Normally 1-3 years,some clients use for 5 years.

*About PSA Oxygen generator (available for 13X-HP zeolite)

PSA oxygen generators utilize the well-known and mature Pressure Swing Adsorption technology. Atmospheric air comprises of 20-21% oxygen and the PSA process utilizes Zeolite molecular sieves to extract this Oxygen from air. Oxygen at 93% is delivered, while the nitrogen adsorbed by the molecular sieves is vented back into air through the exhaust line.

PSA process consists of 2 vessels filled with Molecular Sieves and Activated Alumina. Clean compressed air at 30° C temperature is passed through one vessel and oxygen comes out as product gas. The exhaust gas (Nitrogen) is discharged back into atmosphere. Upon saturation of the molecular sieve bed, the process switches Oxygen generation to the other bed by automatic valves, while allowing the saturated bed to undergo regeneration by depressurization and purging to atmospheric pressure. Thus 2-vessels keep cycling alternately in Oxygen production and regeneration ensuring Oxygen gas is continuously available to your process.

②:Picture reference of PSA Oxygen Generator

③:Equipment components and technical indicators:

------PSA oxygen generator is made of air compressor,cold dryer machine,degreaser,adsorption system,oxygen buffer tank,control system.

------Technical indicators↓↓

Purity:93%+3%(standard type 93%)

Pressure:≥0.2Mpa

Dew point:<-40℃(under normal pressure)

Oxygen production quantity:3~200Nm3/h

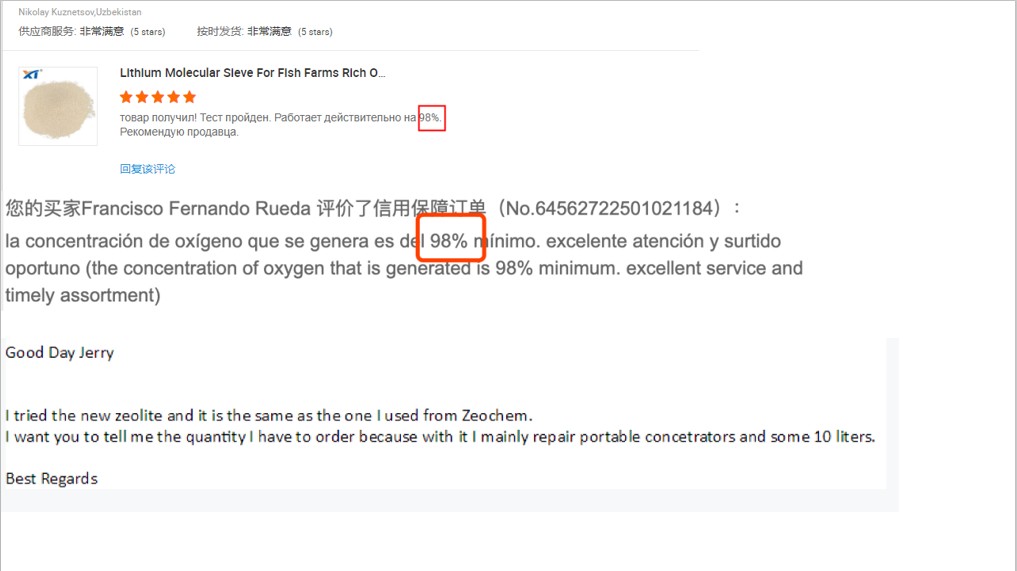

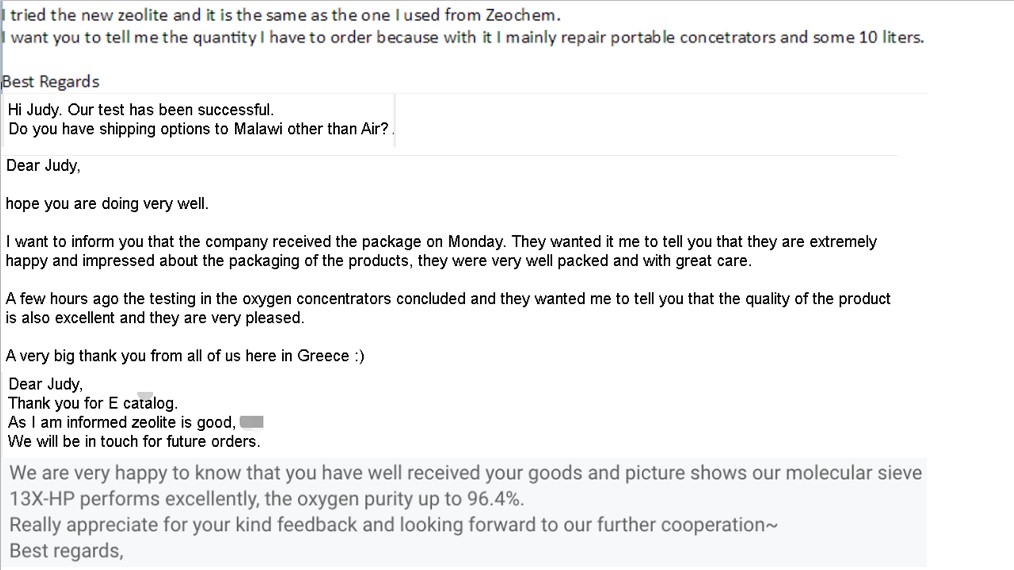

*Testing feedbacks from some clients: