1. Product Introduction

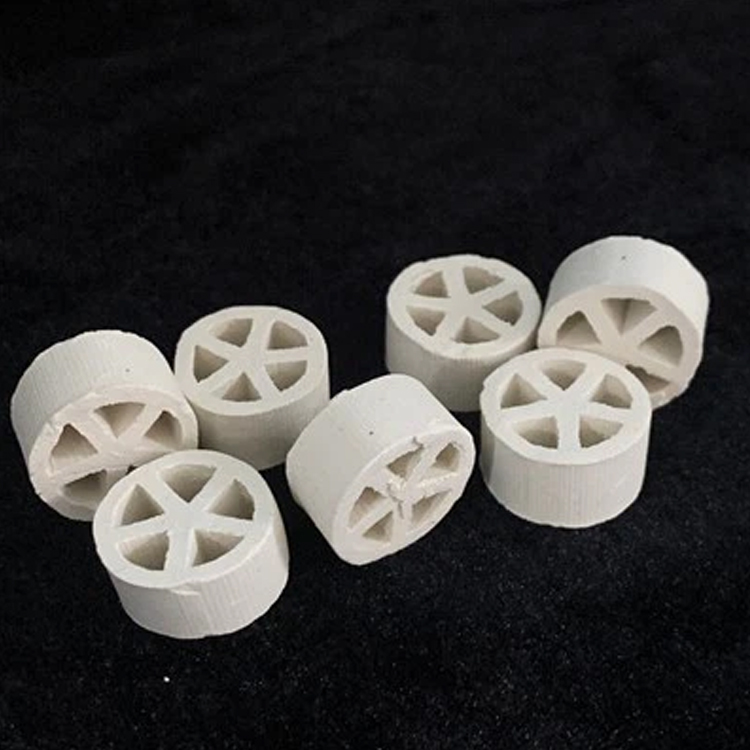

Ceramic Penta ring packing is also called wheel-shaped protective agent, gear-shaped protective agent, ceramic Penta ring, AIG-1 protective agent, etc. The product is made of halloysite kaolin, high-strength viscous refractory clay, and aluminum-oxygen raw materials, which are shaped, dried, and fired at high temperature. It has good acid and alkali corrosion resistance, high mechanical strength, and long service life. At the same time, it has high porosity, large specific surface area, is not easy to cause drift and channel flow, has small gas-liquid flow resistance, fast gas-liquid flow, large contact surface, good gas-liquid separation effect, and high gas-liquid separation efficiency.

2. Product Applications and Advantages

Ceramic Penta ring packing adopts a three-Y ring structure. Compared with spherical proppant, it not only increases the mechanical strength but also increases the specific surface area, thereby reducing system resistance. It can be widely used as catalyst support and covering materials in petroleum, chemical, natural gas, coal chemical and other industries.

The product has been proven by users that under the same reactor and the same operating conditions, compared with porcelain balls, the vapor and liquid distribution is more uniform, the flow rate is significantly increased, the system resistance is significantly reduced, and the catalyst does not agglomerate or burn, thus extending the The service life of the catalyst and the operation cycle of the device are affected.

Application Scope:

The wheel-shaped protective agent is mainly used in petroleum refining, environmental protection, coal chemical industry and other places to replace inert alumina proppant, inert porcelain balls and open-hole porcelain balls. Such as ethylbenzene, styrene, polypropylene, acrylonitrile, PTA and other petrochemical industries and coal chemical industry, synthetic ammonia, coal to methanol, coal to propylene, coal to oil; hydrogenation, hydrogen production, catalytic reforming, Product refining, light hydrocarbon processing and other fixed bed reactors, synthesis towers, conversion furnaces, Claus reactors, hydrogenation tanks, sulfur recovery, two-stage conversion furnaces and other devices。