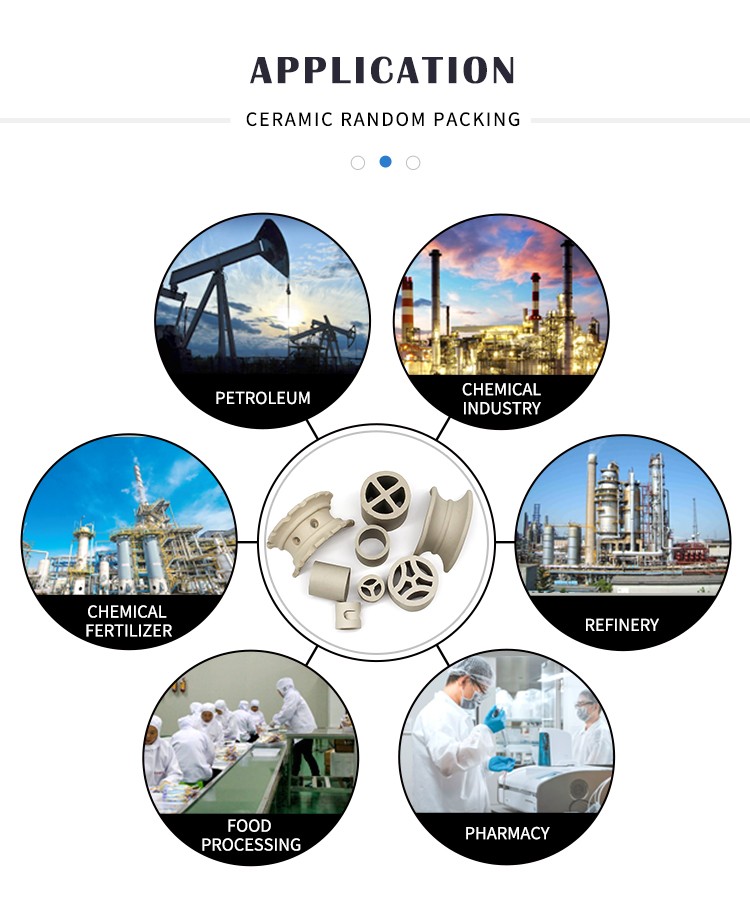

Ceramic Cascade Mini Ring is for chemical exchange and used in the chemical industry for reactant contact optimization. In the column it is important to maintain an effective mass transfer, which will support a large surface area for mass transfer.

XINTAO Ceramic Cascade Mini Ring, absorbs advantages of Ceramic Short Raschig Ring and improves Ceramic Pall Ring. Height diameter ratio of the ring is 1:2 and taper rolled edge is added to one end. It reduces resistance when the gas goes through the machine bed and increases flow rate.

Ceramic Cascade Mini Ring, due to its structural characteristics, gas and liquid are distributed evenly and contact area of gas and liquid is increased, thus improving mass transfer efficiency. It can resist to corrosion of various inorganic acids, organic acids and organic solvents except hydrofluoric acid, and can be used in high or low temperature conditions.

Model: | Ceramic Cascade Mini Ring | |||||

Diameter (mm) | D*H*T (mm) | Surface area (m2/m3) | Free volume (%) | Number (pcs/m3) | Bulk density (Kg/m3) | Dry Packing Factor (m-1) |

25 | 25*20*3 | 270 | 74 | 74000 | 624 | 172 |

38 | 38*30*4 | 192 | 80 | 16000 | 700 | 192 |

50 | 50*30*5 | 108.8 | 78.7 | 9091 | 516 | 223 |

76 | 76*45*7 | 63.4 | 79.5 | 2517 | 426 | 126 |