Ceramic Penta ring packing is also called wheel-shaped protective agent, gear-shaped protective agent, ceramic Penta ring, AIG-1 protective agent, etc. The product is made of halloysite kaolin, high-strength viscous refractory clay, and aluminum-oxygen raw materials, which are shaped, dried, and fired at high temperature.

Product Introduction

Ceramic Penta ring packing is also called wheel-shaped protective agent, gear-shaped protective agent, ceramic Penta ring, AIG-1 protective agent, etc. The product is made of halloysite kaolin, high-strength viscous refractory clay, and aluminum-oxygen raw materials, which are shaped, dried, and fired at high temperature. It has good acid and alkali corrosion resistance, high mechanical strength, and long service life. At the same time, it has high porosity, large specific surface area, is not easy to cause drift and channel flow, has small gas-liquid flow resistance, fast gas-liquid flow, large contact surface, good gas-liquid separation effect, and high gas-liquid separation efficiency.

Technical Parameter:

Model: | Ceramic Penta Ring | |||||

Diameter (inch) | Diameter (mm) | Void ratio (%) | Surface area | Bulk Density (kg/m3) | Bulk Quantity (pcs/m3) | Dry fill Factor (m-1) |

| 1'' | 25*25*3 | 78 | 175 | 520 | 64000 | 565 |

1.5'' | 38*38*4 | 80 | 118 | 470 | 14000 | 356 |

2'' | 50*50*5 | 81 | 72 | 450 | 6300 | 252 |

Remarks:

1. Commonly used specifications for ceramic penta ring packing include Ф3, Ф6, Ф10, Ф13, Ф16, Ф20, Ф25, Ф38, Ф50, Ф76, (mm).

2. Other specifications can be negotiated and manufactured according to user needs.

3. Similar to the selection of porcelain balls, proppant is generally selected according to the relationship between the diameter of the main catalyst particles increasing from the inside to the outside. Usually two of these specifications are used, and in some applications only one specification is required.

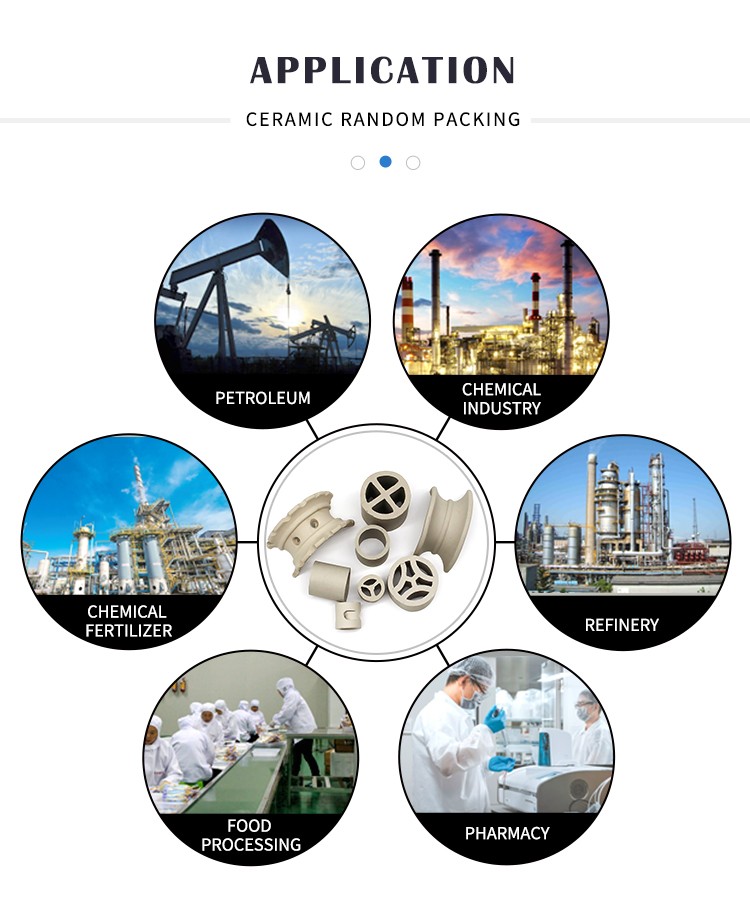

Application Scope:

The wheel-shaped protective agent is mainly used in petroleum refining, environmental protection, coal chemical industry and other places to replace inert alumina proppant, inert porcelain balls and open-hole porcelain balls. Such as ethylbenzene, styrene, polypropylene, acrylonitrile, PTA and other petrochemical industries and coal chemical industry, synthetic ammonia, coal to methanol, coal to propylene, coal to oil; hydrogenation, hydrogen production, catalytic reforming, Product refining, light hydrocarbon processing and other fixed bed reactors, synthesis towers, conversion furnaces, Claus reactors, hydrogenation tanks, sulfur recovery, two-stage conversion furnaces and other devices.