Introduction

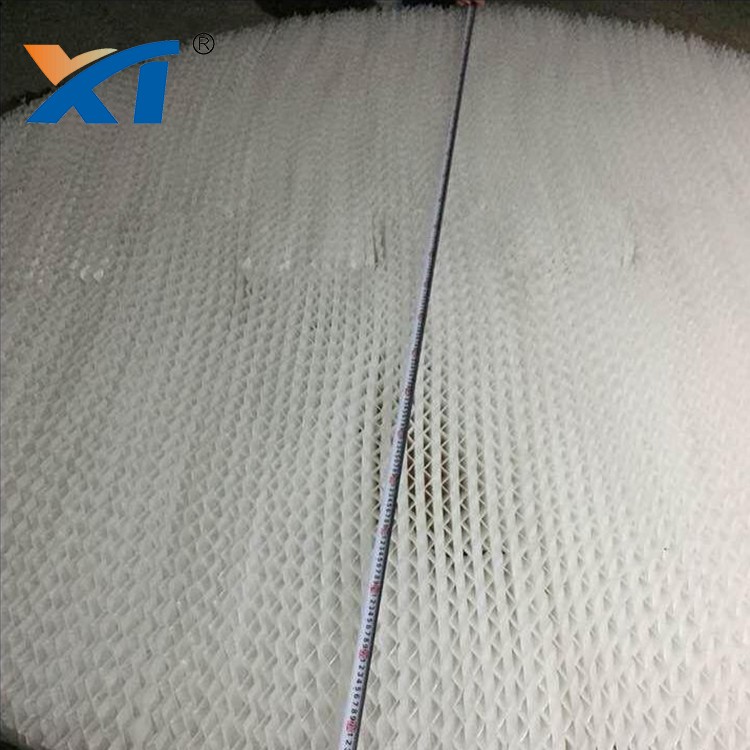

Mass transfer plastic structured packings are manufactured by welding profile-shaped plastic foils onto each other. Two aspects are important:

Even liquid distribution from the structure of the whole packing The profile-shaped foils as well as the structure reached by the inclination of the foils towards each other (channel inclination) achieve an even liquid distribution throughout the packing for low up to very high liquid loads.

High rate of mass transfer by profile-shaped foils,The wave-like profiles (inner structure) of the single foils assure a continuous thorough mixing of gas and liquid. This constant renewal of the gas/liquid boundary results in high mass transfer rates.

This design proves to be more efficient than for example random packings. Tests have shown that structured packings reach a significantly higher throughput and a lower pressure drop at the same level of mass transfer performance.

Technical Parameter

Model | Specific surface(m2/m3) | Void ratio(m2/m3) | Pressure drop (Pa/m) | Theo. plate(m-1) | Liquid load (m3/m2.h) | Max. Factorm/s (Kg/m3)-1 |

SB-125Y | 125 | 98 | 200 | 1.0-2.0 | 0.2-100 | 3 |

SB-125X | 125 | 98 | 140 | 0.8-0.9 | 0.2-100 | 3.5 |

SB-250Y | 250 | 97 | 300 | 2.0-2.5 | 0.2-100 | 2.6 |

| SB-250X | 250 | 97 | 180 | 1.5-2.0 | 0.2-100 | 2.8 |

| SB-350Y | 350 | 95 | 200 | 3.5-4.0 | 0.2-100 | 2.0 |

| SB-350X | 350 | 95 | 130 | 2.3-2.8 | 0.2-100 | 2.2 |

| SB-500Y | 500 | 93 | 300 | 4.0-4.5 | 0.2-100 | 1.8 |

| SB-500X | 500 | 93 | 180 | 2.8-3.2 | 0.2-100 | 2.0 |

Application

Widely used in the operation of absorption and decomposing absorption units, it's especially used in the production procedure of heavy liquid loading and high operative pressure, such as hydrochloric acid (HCl) and sulphuric acid (H2SO4) production, deaerating CO2 and H2S from natural gas, drying chlorine, making ammonia liquid, waste gases purification and decomposing absorption deaeration apparatus.