Ceramic Crossing Ring were developed from raschig ring. It has cross structured which increase performance by increasing the surface area.

XINTAO Ceramic Cross Partition Ring is based on increased surface area of filter to enhance the efficiency of mass transfer on the idea and developed a new ceramic packing, the structure is added in the raschig rings in the cross partition. I n general, this packing the large size, only applied to neat pile, the current cross ring is generally used as lumber distribution layer with the bottom support. 80-150mm size of the ceramic can be used for supporting cross ring material, porosity greater than 60%.

Model: | Cross Partition Ring | |||||

Diameter (mm) | D*H*T (mm) | Surface area | Free volume (%) | Number per m3 | Bulk density (Kg/m3) | Dry Packing Factor (m-1) |

50 | 50*40*50*5 | 145 | 50 | 6400 | 600 | 565 |

80 | 80*64*80*8 | 120 | 56 | 1950 | 820 | 356 |

100 | 100*80*100*10 | 110 | 53 | 1000 | 850 | 252 |

120 | 120*96*120*12 | 75 | 55 | 370 | 860 | 146 |

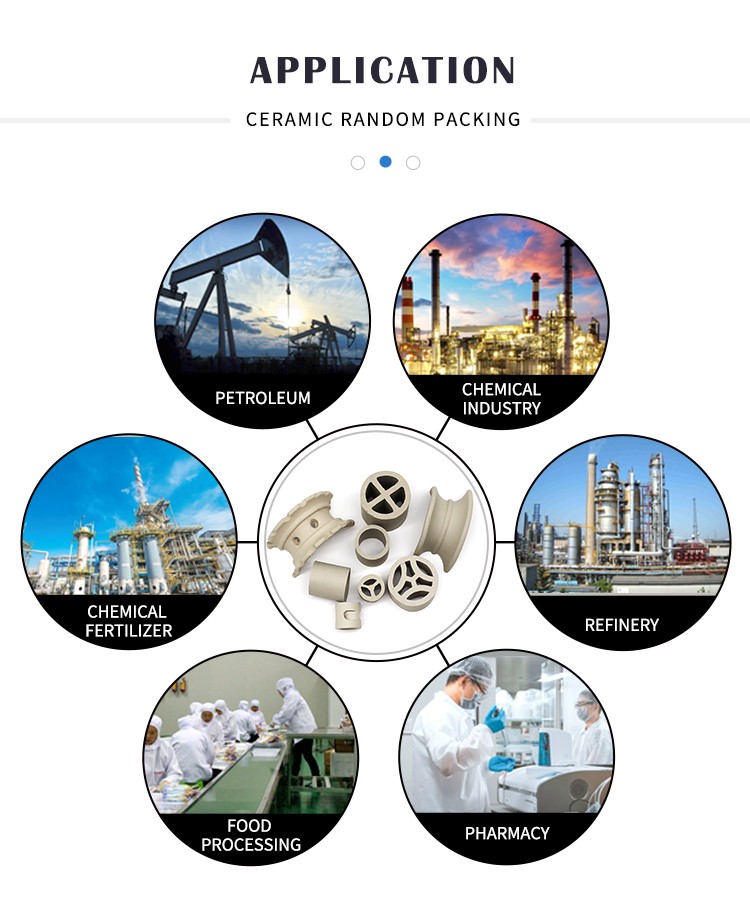

Typical Application

a) Have excellent acid resistance and heat resistance.

b)It can resist to corrosion of various inorganic acids, organic acids and organic solvents except hydrofluoric acid.

c)Used in high or low temperature conditions.

d)Used in the drying columns, absorbing columns, cooling towers, scrubbing towers and actifier columns in chemical industry, metallurgy industry, coal gas industry, oxygen producing industry, etc.